As previously examined, the battery pack design process for electric vehicles (EVs) is not a linear one. It requires close collaboration and teamwork between the battery pack design team and the body in white (BIW) team. As well as considering how the pack will sit within the body of the vehicle, it is essential throughout the design process for all EV engineering teams to consider the manufacturability of the battery pack and also to make sure that the battery pack design is such that it be manufactured easily within the framework of a company’s manufacturing capabilities.

If the various teams do not pay attention to how the manufacture of the battery pack fits into a company’s manufacturing capabilities until the end of the design process it is likely to lead to significant delays and spiralling manufacturing costs.

Getting an accurate assessment

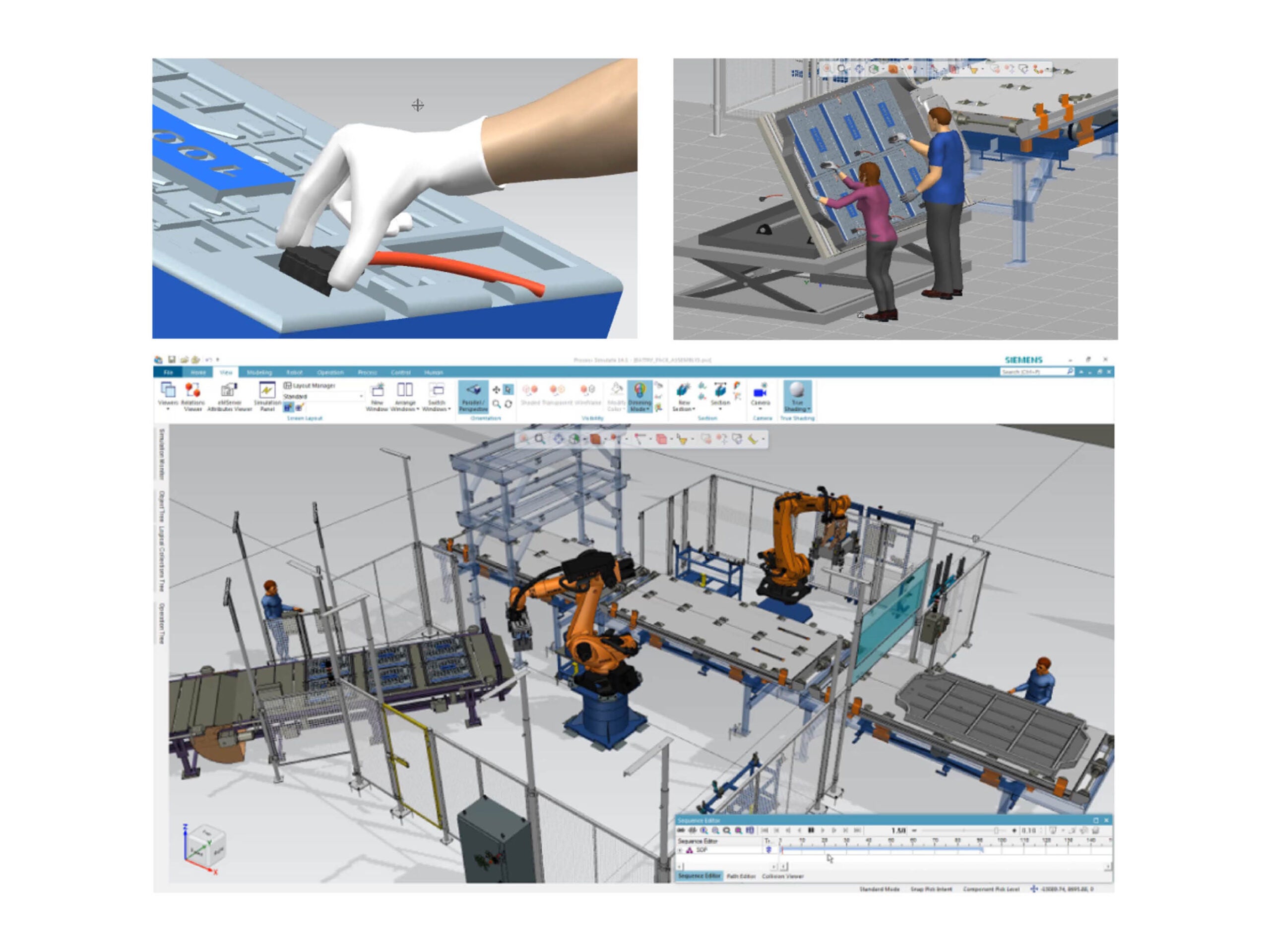

Manufacturing simulation software that is seamlessly integrated with CAD can be used by all teams early in the design process to ensure an accurate assessment of a design from a manufacturing perspective. It is important in order to assess the ability of a design to be built in the company’s factories, while maximizing manufacturing throughput and ensuring the efficiency of both manual and automated manufacturing steps. The simulation can also pinpoint design modifications that can be made to enhance the manufacturing process.

Running a simulation can show how much of a manufacturing plant should be manual, fully automated or a combination where people and robots collaborate. For instance, battery pack components can be heavy, which will drive up the level of automation in the assembly process. On the other hand, manual assembly is better suited for complex, detailed operations. Efficiency lies in balancing the automation and manual processes.

The simulation can also inform the layout and ergonomics of the workplace design. For example, it can determine if a particular task may be difficult to reach for employees of different heights. The simulation enables the development of appropriate workstations and tooling. The resulting lowers risk while ensuring high levels of efficiency as well as operator health and safety.

Another aspect to consider is the introduction of new materials. As traditional BIWs were primarily steel and assembled with traditional spotwelding processes, in an effort to reduce weight many new body designs may include new materials that cannot be welded with traditional processes. Simulation can be used to assess the impact to manufacturing resulting from the introduction of this new equipment and unfamiliar assembly processes.

Production planning and validation

With digital production planning tools, planners can evaluate production line configurations and entire factory layouts to optimize manufacturing operations by defining a virtual model of a manufacturing facility. The engineers can examine and validate the variation in work content in any given workstation or perform line-balancing analysis to ensure that workstations and operators are neither under or over-worked. If needed, an engineer can then quickly reconfigure the allocation of operations to work stations to resolve issues or improve performance.

Simulation is also essential to assess the overall impact of production ‘flow’ in order to have a granular understanding of production costs and environmental impact. The simulation can also be used to show how much energy is consumed in the production process. With the drive to more sustainable production a change to the design might be considered if it would lead to reduced energy consumption. Use of simulation software that understands your costs of production, resource allocation, and how they are used can determine the most efficient production process.

Ultimately, simulation can be used to establish a virtual production that fits the product specification and feeds back information to enable an assessment – early in the design process – of what needs to be changed in product design, the production process or both, in order to optimize production and reduce cost.